Engineering and health team up to design and produce face shields

A team of engineers, physicians, researchers and designers from the University of Illinois at Urbana-Champaign and Carle Health has developed and launched production of a face shield for health professionals responding to the COVID-19 pandemic.

The design specifications and instructions for use have been made public, and can be downloaded here: https://covidPPE.grainger.illinois.edu .

The face shield project is part of a larger Personal Protective Equipment (PPE) design initiative led jointly by The Grainger College of Engineering and the Carle Illinois College of Medicine’s Health Maker Lab, according to Martin Burke, MD, Ph.D., Associate Dean for Research at Carle Illinois College of Medicine.

“The goal of the PPE initiative is to leverage the collective power of the Health Maker Lab to respond to the urgent need to help front-line healthcare workers,” Burke said. “Barrierless collaboration between experts in medical sciences, engineering and design, in partnership with physicians, nurses and community members, has enabled extraordinary innovation in a time of crisis.”

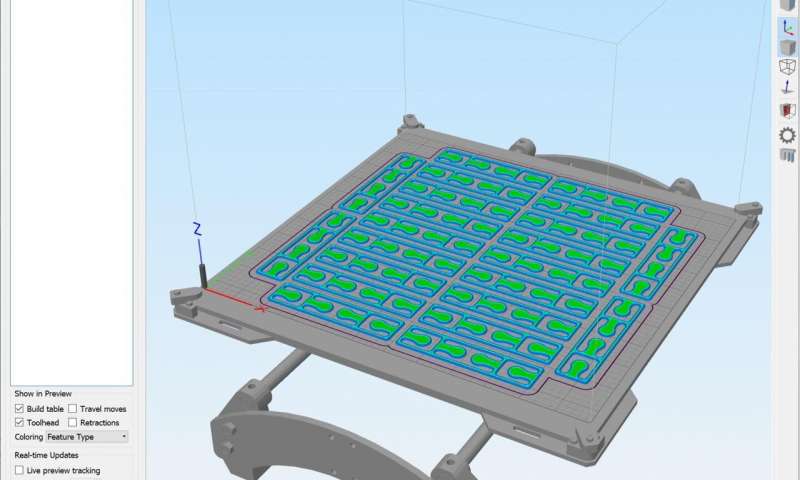

Over a three-week period, the team designed and fabricated face shield components, solicited feedback from healthcare workers in a clinical setting at Carle Foundation Hospital, and received guidance under the Coronavirus Disease 2019 (COVID-19) public health emergency from the U.S. Food and Drug Administration to fabricate these devices, said Irfan Ahmad, Ph.D., Executive Director of the Health Maker Lab, Assistant Dean for Research, Carle Illinois College of Medicine, and Executive Director for Interdisciplinary Initiatives for the Grainger College of Engineering.

“Healthcare workers in Champaign County will begin beta testing a small batch of prototypes this week. The university plans to produce at least 2,000 face shields to support short-term needs,” Ahmad said.

“We have conducted material availability research, and are partnering with local manufacturers like ShapeMaster, Inc., Wagner Machine Co. and others, and seeking grants for them to produce the face shields on a larger scale,” stated Lisa Bievenue, Director of Informatics Program, and of the CU Community Fab Lab.

“Our primary design criteria were all about the needs of health care workers, but we also wanted to enable rapid and cheap fabrication, easy assembly, and reusable frames that can be quickly sanitized with a range of approved techniques,” stated face shield team lead Jeremy Guest, Ph.D., Associate Professor of Civil and Environmental Engineering.

“The team is collaborating to design and test prototypes for other PPE products as well as sterilization technologies, including N95 respirators, disposable and reusable gowns, masks and caps, and mid- and small-scale sterilization technologies,” said Helen Nguyen, Ph.D., Professor, Department of Civil and Environmental Engineering and lead PI on the PPE project. “Dozens of professionals, from engineers, physicians and researchers to costume designers, staff and students, and community members are contributing their expertise and talents on these projects.”

Source: Read Full Article